Environment & Energy

The group Environment & Energy addresses current scientific problems surrounding biogas, biological energy systems, the biodegradation of pollutants as well as entry pathways of microplastic into the environment.

Biogas

Biogas, which is a mixture of CH4 and CO2, could play a major role in the supply of sustainable energy for our society. Biogas is produced by consortia of strictly anaerobic bacteria, biomass and biological waste artefacts. Despite its obvious significance, the microbiological relationships within such biogas plants is poorly understood. Almost all publicly available data was collected as part of short-term laboratory experiments conducted under standardized conditions, which could only approximate the technical conditions. This makes it very difficult to predict how biogas production will react to changing process parameters.

Microbial Fuel Cell

The metabolism of bacteria is driven by electron transfer to chemical acceptors. However, some bacteria are able to transfer the liberated electrons during metabolism to an external acceptor, for example an electrode. This capability is used in the microbial fuel cell (MFC). With an MFC, electric current can be generated when a microbially catalyzed release of electrons takes place on the anode side and subsequent electron uptake at the cathode. Therefore, the microbial fuel cells consist essentially of three parts: a biological cell, a chemical cell and a cation-selective membrane.

Wastewater treatment

Wastewater treatment plants provide an irreplaceable contribution to the purification of municipal and domestic wastewater. The main impurities in these effluents are organic. Therefore, modern multi-stage sewage treatment plants always include a biological purification stage in which microorganisms metabolize such impurities, imitating the natural self-purification of water bodies. The big challenge in the biological treatment stage is the intensification of the natural cleaning process. For this purpose, on one hand, many active Microorganisms must be present in the system, on the other hand, they must be optimally supplied with oxygen.

ZET – Center of Energy Technology

The Chair of Process Biotechnology is an engaged member of the Center of Energy Technology (ZET). This collaboration allows for an interdisciplinary research approach in innovative research areas such as Integrated Energy/Sector Coupling, energy self-sufficient buildings and high-voltage direct-current transmission. The research focus of the chair consists of biogas and compost plants, microbial fuel cells as well wastewater treatment. Its long-term experience in biological environmental sciences and process engineering and the microbial communities found therein provides a broad area of expertise for the ZET. Further information can be found on the website of ZET.

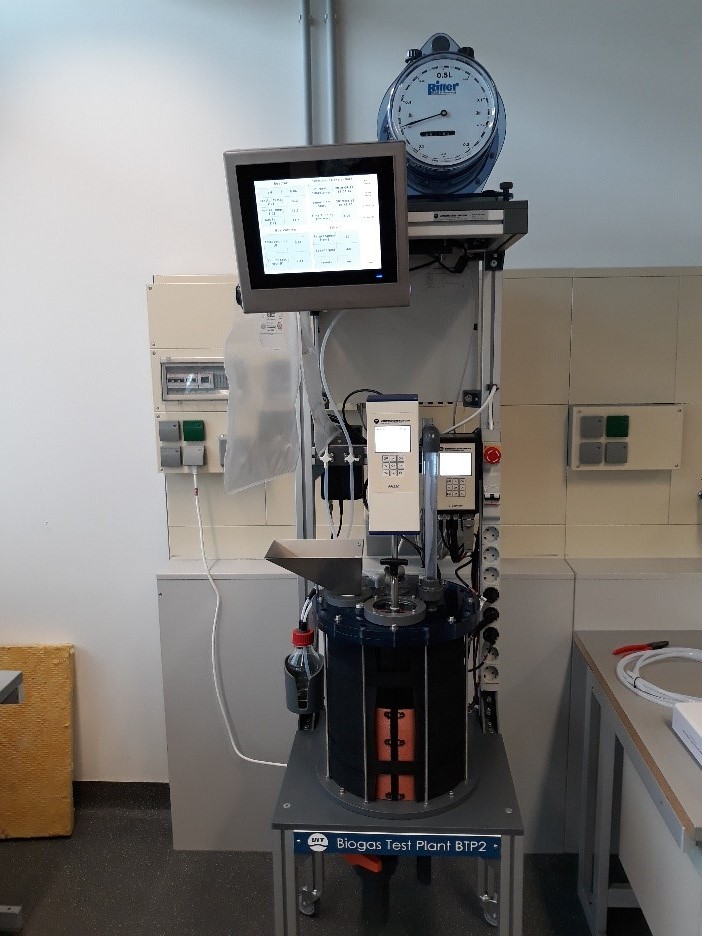

Scaling of the process of anaerobic digestion: aspects of scaling, process stability and effectivity

The focus of the project is to determine the influences of the digester size on the process stability and effectivity. There is a great amount of data obtained on different scales, and the question within this doctoral project is how to ensure a successful scale-down of the process, which can describe and predict potential changes during industrial scale-processes. Further questions are how the microbial population changes over time in different-size digesters and whether the population in bigger reactors is more stable.

The aim of the topic is to identify scaling-relevant parameters (physical, chemical, and biological). The process of anaerobic digestion is run in different-size laboratory reactors in batch and continuous mode. Scaling-relevant equations are derived and coupled with external data from industrial-scale plants and results obtained on the laboratory-scale.

“ZET-Field Test Future of Energy Wunsiedel”

The aim of this project is the realization of one of the biggest German Power-to-Gas (PtG) plants. H2 is to be extracted via water electrolysis using excess power from sustainable sources. H2 and O2, the electrolysis products, can be stored without high losses, unlikely electrical power. In order for the electrolysis to present a viable solution from an economic standpoint, an application for the produced O2 also has to be integrated. The current research investigates the optimization of the biological stage of sewage plants through the input of the excess O2 produced in the PtG plant. Current state-of-art technology utilizes pressurized air, with oxygen being a limiting factor in the purification of wastewater. Therefore, increasing the oxygen partial pressure should increase the cleaning performance of the wastewater treatment plant. The influence of increased oxygen especially on the microbial community, which is key for a stable process, is being investigated. Focus are the microbial composition, the metabolic network, and the degradation rate of pollutants.

Research Partners:

- Department of Engineering Thermodynamics and Transport Processes, Prof. Brüggemann, University of Bayreuth

- Chair of Chemical Engineering, Prof. Jess, University of Bayreuth

- Chair of Electrical Energy Systems, Prof. Danzer, Unversity of Bayreuth

- SWW Wunsiedel

- WUN H2 GmbH

Funding:

ENEGÜLL: Innovation Project “Liquid waste processing for agricultural production of nutrient-optimized fertilizers and for reduction of sustainable resources required in biogas plants”

The intensification of agriculture has led to a surplus of nutrients in soil and accumulation of nutrients in groundwater. As a result, a new EU guideline is placing strict limits on the use of organic fertilizers. The utilization of organic fertilizers is further hindered by its high variance in nutrient composition, which may not be optimized for plant needs. The aim of this EU-funded European Innovation Partnership (EIP) is the processing of substrates such as liquid wastes so that they can be utilized in biogas plants. This reduces the need, and therefore the cultivable area required, for energy crops such as corn, as well as produces concentrated organic fertilizers with a defined nutrient composition. The Chair of Process Biotechnology contributes in the valuation of the biogas yield and the biological behavior of the processed substrate during the biogas process. The participating biogas plants are evaluated from a microbiological standpoint and the results are correlated with the documented gas yields and process parameters as well as the currently achieved fermentation efficiency. Additionally, satellite experiments are being conducted at the chair in systematic fermentations. Aim is the definition of effects of the changed substrate composition on biogas yield and quality, as well as documenting the fermentation residue and defining an optimal substrate composition.

Research Partners:

- LandBeratung Mitte GmbH (Lead)

- Institute of Agricultural Engineering, Prof. Dr. Hartung, University of Kiel

- Bioenergie Gettorf GmbH & Co. KG, Tüttendorf

- Lorenzen Biogas GmbH & Co. KG, Schafflund

- Terrawater GmbH, Kiel

Funding:

Ministry of Energy, Agricuture, the Environment, Nature and Digitalization, Schleswig-Holstein: Funding through the European Union as part of the program “EIP – landwirtschaftliche Produktion und Nachhaltigkeit in der Landwirtschaft”

Optimization of Soil Microbial Fuel Cells for Stable Power Production and Bioremediation

This study is aimed at optimizing soil MFC for stable power density and bioremediation of petroleum hydrocarbon (PAH) contaminated soil. The experiment is designed to study the effects of variables such as electrode spacing, interval of treatment with substrate and types of electrode on the MFC power output and the losses within the MFC systems. The role of urine in stabilizing the power output of the MFCs is of particular interest. The interactions of these variables at their different levels and their treatment effects on the MFCs performance in terms of power production, internal resistances and PAH remediation are being studied. The results from this research will be used to model the output of the MFCs for prediction of their responses to the selected input variables.

Funding:

German Academic Exchange Service

Development of an intensive nitrification module

The aim of this research project is the development and production of an intensive nitrification module. This module allows the implementation of a novel biological purification process, especially for such wastewater, which cannot be processed due to an unfavorable composition of the waste loads or insufficiently through the natural microbiology.

The method is based on the decoupling of the limiting metabolic rate so that it can be integrated as needed and independently of the remainder of the purification process. This is based on the embedding of specifically metabolically active microorganisms in an adapted polymer matrix in the form of fibers. As a result, the active microorganisms are stably fixed. In the matrix, they are optimally supplied with nutrients, but are protected against harsh environmental influences, such as high salt loads.

Research Partners:

- PPU Umwelttechnik GmbH, Bayreuth

- MAILINGER innovative fiber solutions GmbH, Scheuerfeld

- FIBRE Faserinstitut Bremen, e.V., Bremen

Funding:

Project BioComps

ZIM – Central Innovation Programme for small and medium sized enterprises (SMEs)

funded by the Federal Ministry for Economic Affair and Energy

BabbA – Biologically Degradable Bags in Biological Waste Plants: Potential for Displacement of Conventional Plastic Bags, Degradation in Waste Plants, Environmental Relevance

This project researches the usage of biodegradable plastics. The German waste disposal industry is facing a big challenge: on one hand, biological waste should be collected with as little contamination (e.g. from plastic bags) as possible, on the other hand, the total amount of collected organic waste needs to be increased as a large amount of it is being disposed in general waste collectors, by designing organic waste disposal as accessible as possible (through the use of bags). The utilization of biologically degradable plastics could present a solution to this problem. Over the course of this project, the degradation behavior of compostable bags will be investigated in lab and real-life environments, and population surveys at project start and end will be used to compare the subjective perception with observed data regarding biological waste collection habits.

Research Partners:

- Chair of Animal Ecology I, Prof. Laforsch, University of Bayreuth

- Fraunhofer Institute for Chemical Technology (ICT), Karlsruhe

- Institut für Bodenkunde und Standortslehre (IBS), Prof. Kandeler, University of Hohenheim

- BEM Umweltservice GmbH, Ludwigsburg

Funding:

Ministry of the Environment, Climate Protection and the Energy Sector Baden-Württemberg (BWPLUS Baden Württemberg Program “Lebensgrundlage Umwelt und ihre Sicherung”), Project sponsor Karlsruhe PTKA-BWP

MiKoBo: Microplastics in Composts and Organic Garbage Disposal Fermentation Residue and their Entry Pathways into Soil – Identify, Evaluate, Avoid

MiKoBo investigates the environmental system of soil from the standpoint of microplastic entry. Sludge is a common known entry vector for microplastics in soil, but is rarely applied in Germany nowadays. Organic fertilizers have until now rarely been considered for its potential for microplastic contamination of soil. Germany operates within a system of waste separation, where organic waste is collected and processed separately in compost and organic waste plants, creating valuable organic fertilizers. At the same time, organic waste is often contaminated with synthetic material, most often in the form of plastic bags.

The MiKoBo project is created to assess the degree of microplastic contamination of soil created through organic fertilizers produced in this manner. A careful evaluation is required since the positive impact of the fertilizer might outweigh the possible damage caused through microplastic contamination. The entire process chain is considered, starting with organic waste, its processing in technical plants and subsequent post-processing treatments, in order to understand the relevant process engineering and microbiological parameters. Particular focus is put on biodegradable plastics, which might present a partial solution. The results will be verified using satellite plants with standardized microplastics and will be used for legislature recommendation guidelines.

Research Partners:

- Chair of Animal Ecology I, Prof. Dr. Laforsch, University of Bayreuth

- Institute for Sanitary Engineering, Water Quality and Solid Waste Management (ISWA), Prof. Kranert, University of Stuttgart

- Institut für Kunststofftechnik, Prof. Bonten (IKT), University of Stuttgart

- Institute of Biomaterials and Biomolecular Systems (IBBS), Prof. Weiss, University of Stuttgart

- Institut für Bodenkunde und Standortslehre (IBS), Prof. Kandeler, University of Hohenheim

- Fraunhofer Institute for Chemical Technology (ICT), Dr. Forberger, Karlsruhe

Funding:

Ministry of the Environment, Climate Protection and the Energy Sector Baden-Württemberg (BWPLUS Baden Württemberg Program “Lebensgrundlage Umwelt und ihre Sicherung”), Project sponsor Karlsruhe PTKA-BWP