Technical Microbiology

The research group Technical Microbiology utilizes biofilm engineering, a key technology in industrial biotechnology, to produce process-adapted artificial biofilms, so-called biocomposites, in which the organisms ("whole-cell biocatalysts") are embedded in a tailor-made synthetic polymer matrix. This technology is essential for intensification of long-term stability of industrial biotechnological processes.

The biocomposites consist mainly of micro-fibers, which are produced by old (like wet-spinning) and novel technologies (e.g. electro-spinning). The bacteria are inside the micro-fibers and alive. There, they find perfect conditions for their metabolic conversion, they are protected against harsh environments and pH-shifts. The micro-fibers can be produced to tissues and filter-modules, which can be easily integrated in biotechnological processes. This technology opens new ways using bacteria in the fields of urban-mining, bioremediation and production of substances which are growth inhibiting or toxic.

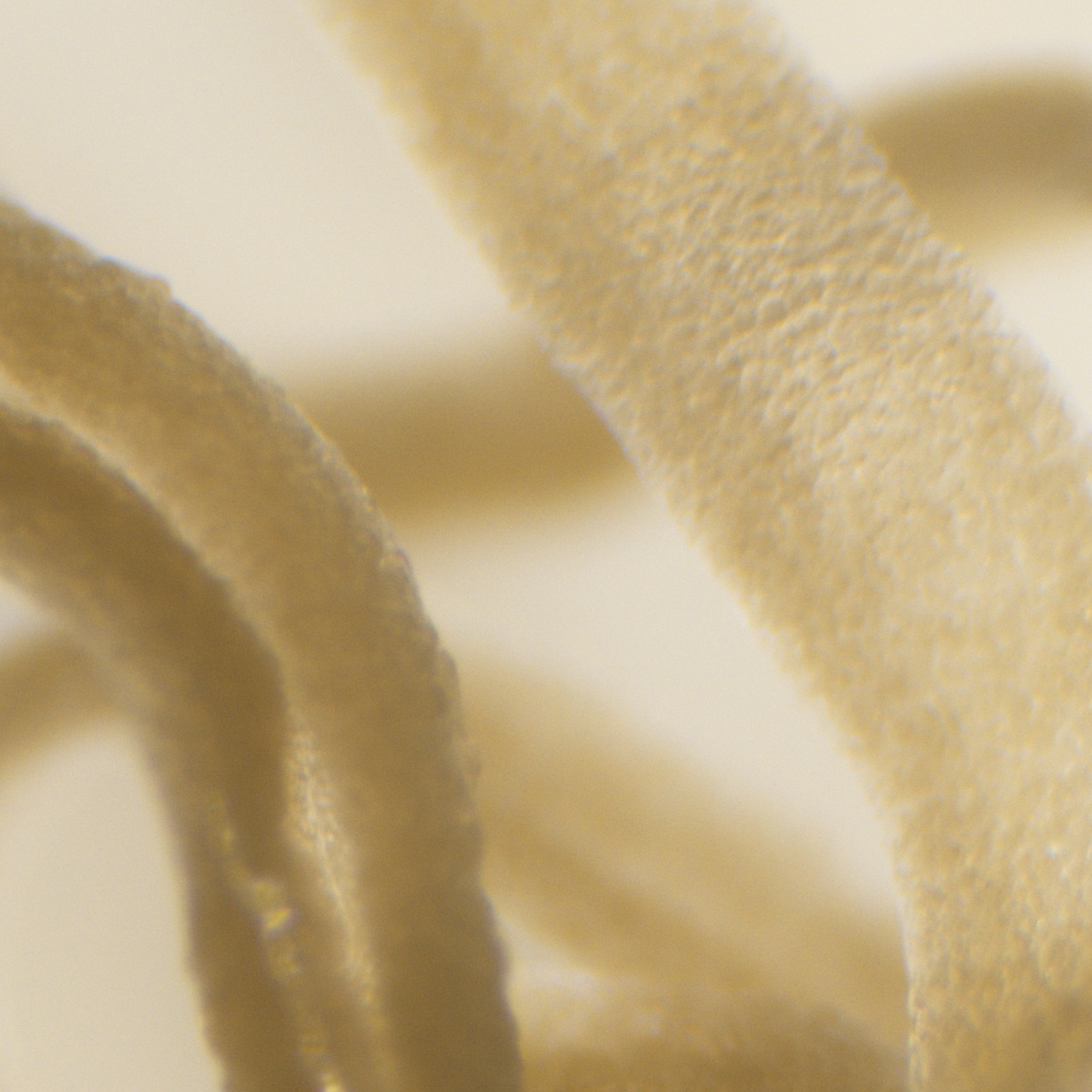

Production of magnetosome in Magnetospirillum gryphiswaldense

Magnetosomes are magnetic nanoparticles produced by microorganisms such as M. gryphiswaldense allowing for orientation in the planetary magnetic field. These nanoparticles exhibit a narrow size distribution and are covered by a biological membrane, making them potentially suitable for a wide variety of biotechnological applications. The membrane-bound proteins can be genetically modified in order to present specific ligands, allowing for targeted stimulation of cells. Large quantities of high purity of magnetosomes are required for these applications. The cultivation of the strictly anaerobic M. gryphiswaldense and the purification of the magnetic particles present current challenges.

Research Partner:

- Chair of Microbiology, Prof. Dr. Schüler, University of Bayreuth

Propioni - Propionic Acid Production for Food Industry

Propionic acid is utilized in food industry as an efficient inhibitor of mold formation. Artificially synthesized or purified propionic acid is a recognized food additive as preserving agent, however requires additional labeling (E280). Food industry is gradually moving away from labelled food additives, giving rise to Propioni, which aims to develop a microbiological fermentation production propionic acid without post-processing. According to the EU regulation of flavorings and food ingredients, no additional labelling is required for propionic acid produced in this manner. A fermentative production of propionic acid is not feasible from an economic standpoint using the current state-of-the-art technologies. The associated costs due to low productivity and product inhibition witnessed in microorganisms resulting in low yields (< 2,5 wt.%) are not competitive with current industry standards. In a collaboration with a player in the food industry, microbiological and process engineering parameters are established to increase productivity and allow the establishment of a competitive microbiological production of propionic acid in the medium-to-long term.

Development of artificial biofilms

This project verified the concept of the artificial biofilm and established and validated exemplary applications in three key areas of industrial biotechnology:

- Environmental biotechnology (nitrite degradation): development and production of an intensive nitrification module for implementation of a novel wastewater treatment process

- Energy technology (microbial fuel cells): Development of a biofilm as anode material

- Biotechnological synthesis of natural products: Propionic acid production in food industry

Conventional manufacturing processes such as spray-drying, wetspinning and electrospinning processes were adapted for the production of artificial biocomposites. The resulting structures such as hollow capsules, microfibers and nonwovens of bacteria/hydrogel suspensions preserved the biological activity of the microorganisms. Additionally, it is possible to form biofilms with microorganisms which show little to no inclination toward biofilm formation in nature. This achieves significant technical progess.

Research Partner:

- Macromolecular Chemistry II, Prof. Greiner, University of Bayreuth

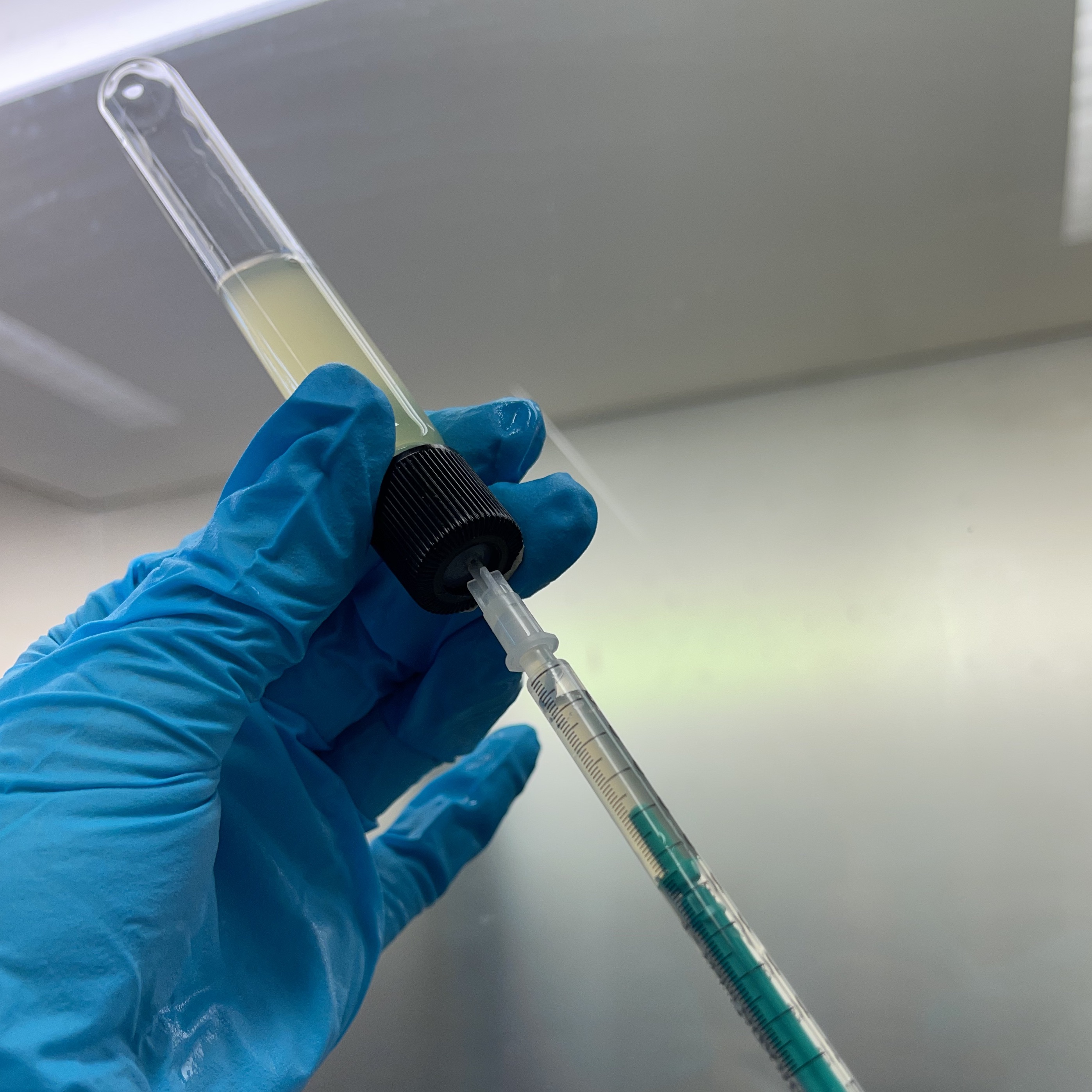

Let´s have a look in our labs: